Insulation Resistance – Fixture Failures

Test Results:

Failures indicated while learning the cable/harness:

- Learned Resistance Errors (with low connection resistance setting).

- Learns Unexpected Connections (with a high Connection Resistance setting).

Failures indicated while testing the cable/harness.

-

- Insulation Shorts during low voltage tests.

- Insulation Resistance or Leakage Failures during high voltage tests.

Necessary Conditions:

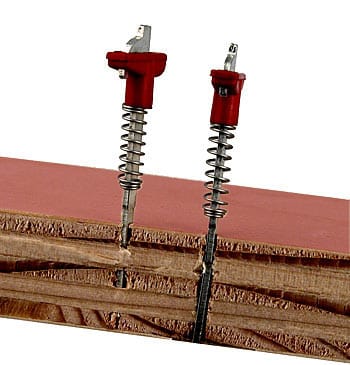

- Fixturing that has uninsulated spring probes or terminals mounted into fixturing materials made of plywood, phenolic, or ESD dissipative materials (often black).

- Painted harness boards that can become mildly conductive.

- Insulation Resistance settings > ~ 20,000 ohms.

Aggravating Conditions:

Conditions that could contribute to, or worsen, the effects of this problem

- Un-insulated spring probes or terminals in close proximity to each other or with significant surface area in contact with the insulating materials.

- Humidity greater than 40%.

Root Cause:

Fixture materials that are expected to be good insulators but are mildly conductive. The following have been found to cause problems:

- Black plastics and black glass epoxy that have carbon added to create Electrostatic Discharge (ESD) dissipative properties.

- Glue in plywood – especially at elevated humidity.

- Some plastics.

- Phenolic materials.

- Some Paints.

Understanding the Failure Mechanism:

Many materials used in test fixturing are thought to be good insulators, but in reality are not as good as the continuity tests you may perform. Nothing is wrong with the cable/harness under test. Only the fixturing has bad insulation. These mildly conductive contaminants might be used in paint to give it color or in plastics to strengthen them or provide better ESD dissipative properties. We have seen some black plastics rated for high resistance contaminated by a prior run with the ESD additives. If a material such as the glue in plywood includes a salt, such as sodium chloride, the insulation resistance is very much a function of humidity.

Confirmation of Root Cause:

One or more of the following might be used to verify the defect:

Remove the cable/harness and use a setting at least 2 times higher than the failing insulation resistance setting. Learn and test without the cable/harness connected. There should be no learned resistance errors on learn and no failures when tested. The higher resistance setting is required because the cable/harness usually connects multiple terminals/probes together creating multiple resistance paths. This reduces the insulation resistance by the typical resistance divided by the number of paths. If there are more than 2 point nets, test at even higher resistances.

In some cases it may be possible to remove the non-insulated terminal or spring-probe from the suspect insulating material of the fixture and still perform the test. If the test then passes, you likely have eliminated the cable/harness as the cause of the failure.

General Recommendations:

( if you plan to perform insulation resistance tests >20K ohms )

- Test fixture materials and paints for IR/leakage before using them.

- Unless you know the insulating characteristic of a material used in your fixture, don’t mount bare spring probes and uninsulated terminations directly into plywood. Provide some form of additional insulation.

- Don’t expect plywood to be a great insulator when humidity is high. You likely can get over 20K ohms but IR tests at over 1 Meg ohm could be compromised.

Painted plywood as a foundation material for your harness building and testing can be a source of IR failures under the right circumstances.

Using phenolic material as your fixture foundation is asking for IR failures. This substance can conduct current under a number of conditions.

Metal brackets in contact with metal shells etc. can also be a source of IR failures due to poor insulation characteristics of the foundation materials.

Case Studies

Problem 1

A fixture in an automated test station had been built to test an over-molded metal circuit for a car fuse-block. IR tests were regularly failing, especially in high humidity. The customer suspected the problem was with the tester.

Discovery

The fixture consisted of spring-probes mounted in a phenolic insulator with cotton cloth used for strengthening. Troubleshooting determined the problem to be leakage in the phenolic material that was exacerbated by humidity.

Solution

The fixture was rebuilt at substantial cost, replacing the phenolic insulator with glass epoxy material such as used in PC boards.

Problem 2

A painted plywood harness board connected to a Signature series tester was resulting in a learned resistance error.* To get a successful learn, the connection threshold had to be raised to 1 Meg ohm. However this created one large net with very high resistance connections. Some harness boards exhibited this problem while other, seemingly similar boards, did not.

* another way to eliminate this learning error is to set the connections threshold at the same level as the insulation threshold. A ‘learn’ will consider anything below the threshold a connection and anything higher than the threshold insulated.

Discovery

Removing the harness-under-test and doing a learn demonstrated the same insulation resistance problems (high resistance connections were learned, with only the test fixture plugged in). Further investigation revealed that the harness board supplier had used a different type of paint than on previous boards. Indeed the new type of paint was confirmed as the source of the problem.

Solution

Fabrication shop returned to using the “non-conductive” type of paint.